Adrian Jaeger didn’t have to think twice when asked why he enjoys working for the University as a precision mechanic: At many companies, precision mechanics spend producing the same components week in, week out. The objective is to produce large quantities. But things are quite different at the University, where it’s never the boring same-old. “There is no typical workday here. The job is varied; you just never know what the colleagues at the Institute will come up with,” says Jaeger. “Sometimes they will need a prototype, sometimes a replacement part; other times they need an idea for a component that has never existed before.”

Researchers discuss whatever job they have for their precision mechanics in detail. Jaeger appreciates the good communication: “We don’t just get an order emailed in to us and the go get started. Instead, we discuss together what the best approach could be, how to proceed. An early-career researcher for example may come to us with drafts of an experiment setup required for his or her doctoral thesis. The objective may be to test how a material behaves under radiation. We would then design components to be made for that one specific application.” Another advantage is how everything is close together at the Institute: “I don’t just hand over the components, then never hear another word about it. Often, researchers will have me come visit the lab due to some adjustments that need to be made. I can also go over and observe for myself how testing is successfully performed using our components.”

Jaeger started out himself as an apprentice at the University of Bonn, in 2013. “Actually, all I knew at that time was that I wanted to work in some tradesman vocation. My mom read an article about apprenticing at the University in Forsch magazine, and then everything took its course,” Jaeger recalls with a grin. Today Jaeger is himself an apprenticeship instructor on the seven-person workshop team, and can’t imagine working anywhere else: “It’s truly a special thing to be able to make parts for Institute research projects that otherwise would not be possible to conduct.”

We get to contribute to the research work, which is a great thing. Where else do you get to have that kind of experience?

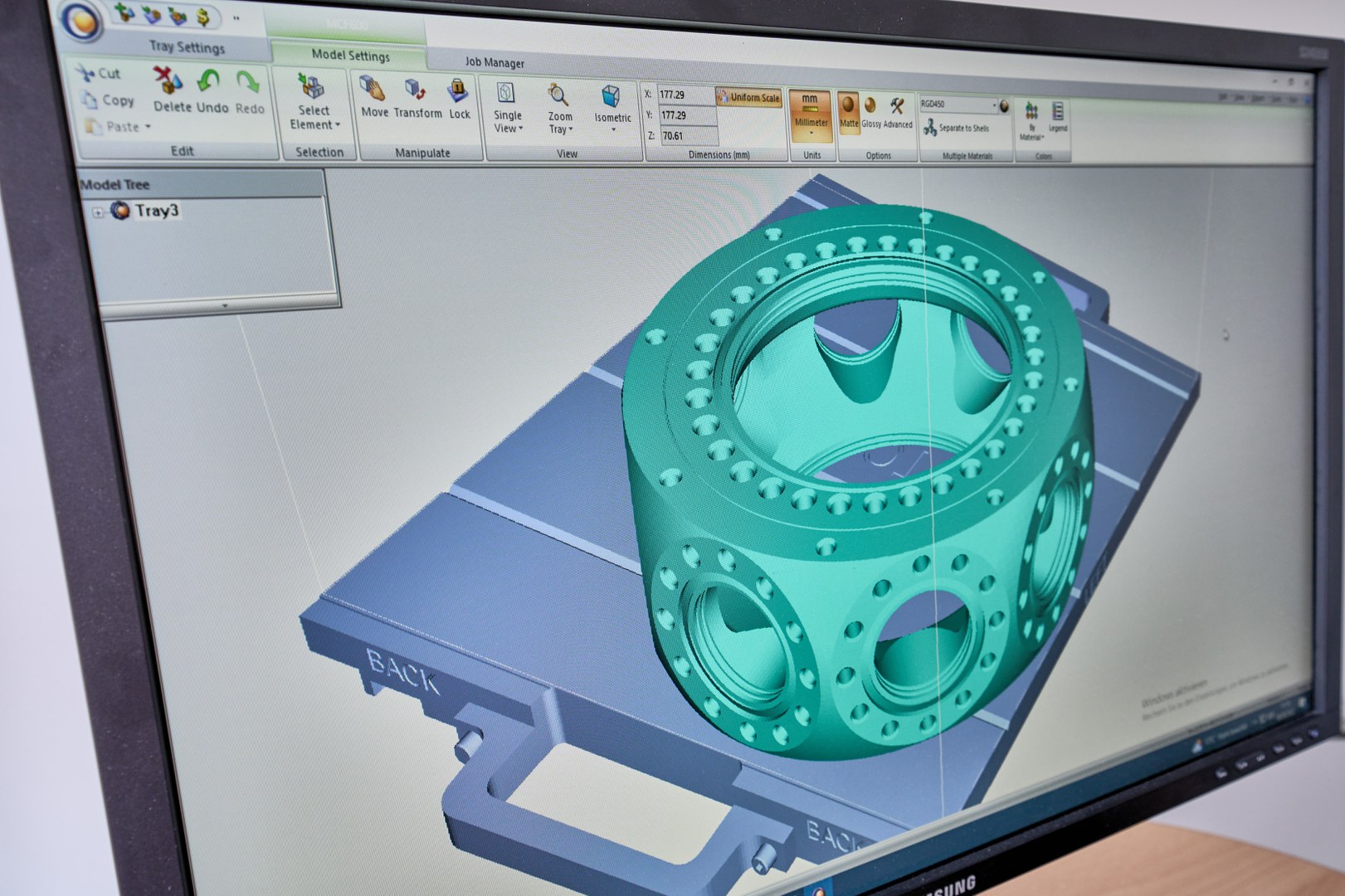

Ilya Geyer agrees, who has been working there since 2009. He has no intention of leaving, because there is nothing he’d rather be doing than making components for research projects. “Our work is highly varied, and very much different from other precision mechanic jobs. Milling, turning, soldering and welding ... we have to get creative and try a lot of different things out. In many cases there is no solution you can just take from a manual. The orders we get are out-of-the-ordinary. We specialize in precision work, and that means down to the μ”. Having the workshop close to the labs is a major advantage. “I can just stroll right over and have a look at the experiment setup. That makes things easier than having to work off a rough sketch.” When the components he builds function as planned, Geyer feels pride of accomplishment. “Sometimes the preparations take longer than actual production. A lot of thought and planning goes into ensuring that the installed components will properly work later on during the experiment. If everything ultimately goes well, the researchers will come over and let us know, and that’s a great feeling.” The workshop staff have a spectrum of ultra-modern tools at their disposal: a conventional milling machine, a CNC lathe, a five-axis milling machine and a 3D printer. “Over the last ten years we have done a lot of investing and modernizing,” says Daniel Kunz, who manages the precision mechanical engineering workshop. An apprenticeship instructor, Kunz knows well that apprentices have little interest in working with outdated machines and methods.

Apprentices who enjoy sophisticated technologies will definitely find they have come to the right place here.

This requires however a willingness to do continuing education—to constantly acquire new skills and knowledge. Like learning CAD: computer-aided drawing for model design. Anyone thinking about becoming a precision mechanic should enjoy working in a digital as well as a precision environment, and have a lot of patience too. “High-precision working is critical for us. as all components need to serve their own designated function. The researchers are relying on us! Individuals with a hectic work style will have a hard time manufacturing complex, ultra-small components,” says Kunz. The summer apprenticeship semester starts out fairly relaxed, with the apprentices performing manual tasks like sawing, filing and soldering. In the second apprenticeship year they start being involved in completing jobs. Some time before that however they will have certainly had a look at the impressive isochron cyclotron (particle accelerator) located more or less beneath the Institute workshop, used by particle physicists to study what holds the world together at its core.